A global pandemic, the war in Ukraine, and unprecedented weather events have exposed the fragility of the global supply chain, resulting in significant disruptions at all levels. Consumers all over the world are experiencing longer wait times for goods, higher prices, and limited supplies of critical products. The US military is not immune from these disruptions and is struggling to actively manage its defense industrial base (DIB) supply chain and avoid substantial impacts to national security. To adequately address these concerns, the Air Force must employ a holistic approach to map and monitor its DIB supply chains, similar to how intelligence analysts create a complete picture of the intelligence environment.

Complex Systems

Supply chains are complex systems comprised of thousands of independent pieces and parts. A problem with one company in the supply chain can have significant and possibly devastating impacts on other companies in the supply chain. For example, a small supplier that produces fan blades for the F-35 could go out of business, resulting in a months-long shutdown of the entire F-35 production line until another supplier is found. A natural disaster or factory fire could take out a fourth- or fifth-tier supplier, and the Air Force would not be notified until the DIB tier-1 contractor brings it to the attention of the program office, typically asking for more time and money.

In complex systems such as supply chains, every variable and every node can have ripple effects across the entire landscape. A supply item previously considered insignificant could be the difference maker in the United States’ current climate of great power competition. Therefore, the Air Force must take actions now to proactively map and monitor its DIB supply chains to fully understand risks to mission that may have been heretofore unknown.

Experts in academia and industry have spent significant time and money attempting to understand supply chains and develop methods to predict disruptions, emergent issues, and risks.1 Due to its importance at the national and global levels, President Joseph Biden issued an executive order in 2021 to push the country to establish more “resilient, diverse, and secure supply chains.”2 One year later, seven cabinet agencies, including the Department of Defense, published “reports identifying key weaknesses in some of the nation’s most crucial supply chains and devising multi-year strategies to address those weaknesses,” and the White House issued a capstone report on its progress.3 Yet despite all the collective efforts, no one method of prediction provides a complete picture of a supply chain and its risks.

Supply Chains Require a Diverse Approach

Throughout the years, the US Intelligence Community (IC) has become proficient at the art of combining multiple sources of information, or intelligence, to understand the nuances of an adversary’s capabilities and intentions. In the same way that IC operations use multiple forms of intelligence—open source, human, signals, imagery, measurement and signatures, and others—and analytical methods to assess and analyze adversary capabilities and intent, the Air Force should use multiple data sources and analytical methods to identify vulnerabilities and assess risks in its supply chains.

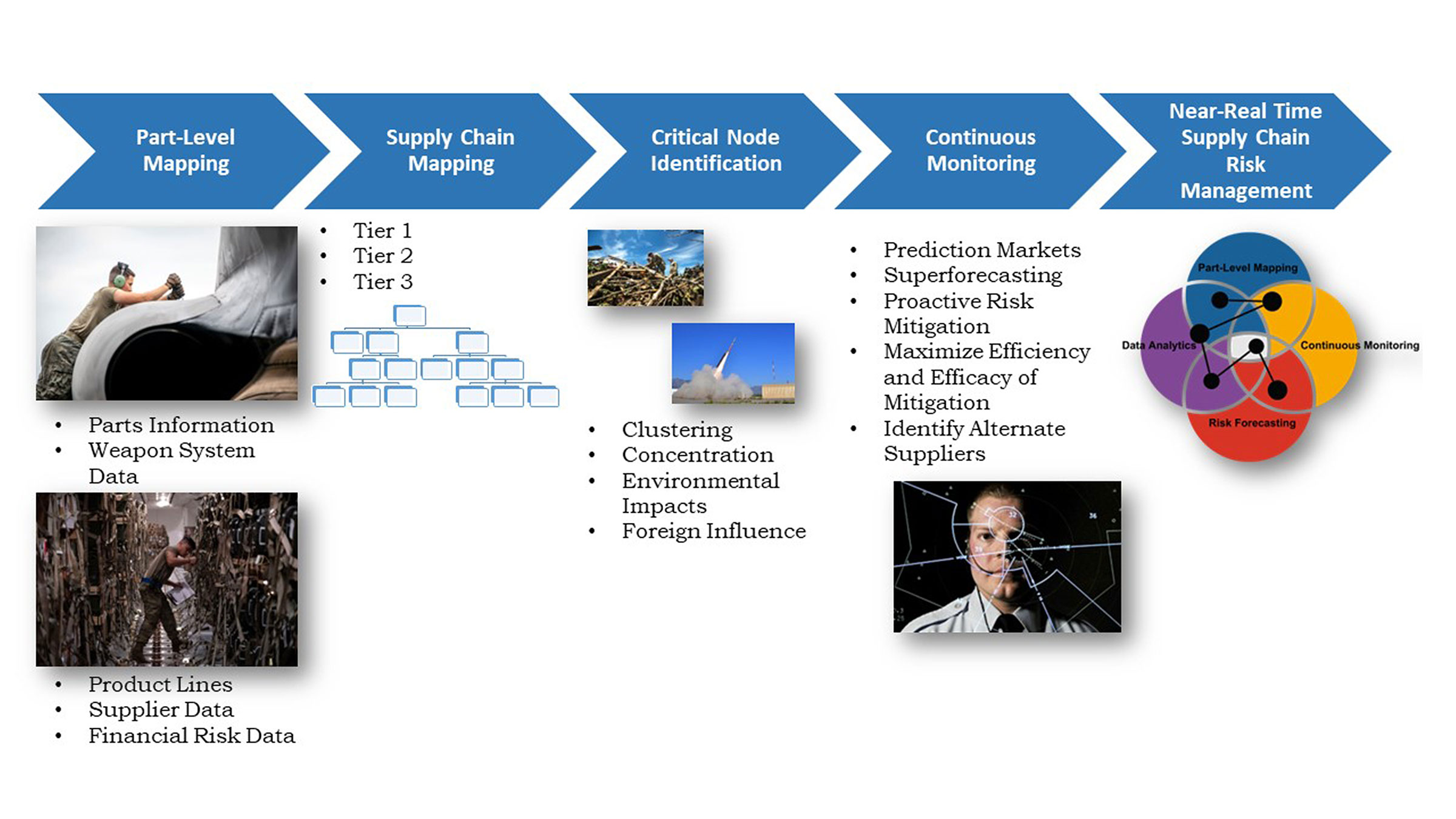

Specifically, the service should use easily accessed data sources for a weapons system to identify the parts, map the supply chain, and identify critical suppliers. Analysts should then monitor suppliers and the flow of supplies for potential risks and disruptions. The following technique will provide the Air Force with the ability to confidently manage the complexity of its supply chain.

Although the Air Force has organizations dedicated to supply chain risk management, including the Air Force Materiel Command Supply Chain Risk Management program team and the 448th Supply Chain Management Wing at Tinker AFB—both focused on Air Force internal supply chains—it relies heavily on prime contractors to provide visibility into its supply chains.4 Visibility into the supply chain is mandated by contract, and DIB prime contractors are required to discover and communicate identified risks and vulnerabilities within a weapons system’s supply chain.5 Under this model, there is little incentive for the defense industrial base to proactively manage its supply chains. For prime contractors, supply chain disruptions often translate into more money and more time earned and sharing detailed information about the lower tiers could mean losing their leverage in the contracting process. If the Air Force is able to solve the problem internally, it could finally hold DIB contractors accountable.

Using the IC approach of proactive analysis would remedy this problem by allowing the Air Force to identify risks at lower tiers without relying on information from the prime contractors. Such analysis would also give the Air Force more leverage in contracting and help it know where it needs to diversify and/or improve resilience of critical supplies. Furthermore, it would allow the Air Force to remove the stovepipe mentality where each project management office is only concerned with its own supply chain. As a result, the layers built into the reporting processes prevent near-real-time notification of supply interruption issues to the Air Force.

Figure 1. Supply chain risk management framework

Obtaining the Data

The first element of this IC approach involves identifying and exploiting useful data sources to illuminate defense industrial base supply chains without relying on DIB prime contractors for information. To help the Air Force overcome its supply chain risk management issues, myriad data sources could be pieced together to assess some level of supply chain risk, but certain sources are critical. The financial investment sector routinely assesses business relationships, as this information, which is then entered into databases, is imperative to building solid investment strategies.

For example, one publicly available source for such business relationships is electronic data gathering, analysis, and retrieval (EDGAR). Publicly-traded companies are required to file EDGAR documents that contain information about their business, including goods and services provided, risk factors, properties, legal proceedings, safety disclosures, financial statements, controls and procedures, and information about company executives.

The Air Force could also potentially use databases created within this sector. For example, one database created by a private equity fund uses a pristine ontology to identify economic relationships, which is another lens through which to view supply chains.6 The equity fund team hand-curates publicly available, unstructured data into usable, structured, precise, and granular data, which can be analyzed to develop business profiles and relationships. In addition, the team’s approach can easily be extended to the private company landscape by pulling in other data sources such as government-owned data, including tax filings, contract documents, and permits and licenses, or public data, including company websites and chamber of commerce information, thereby creating a complete canvas of the ecosystem.

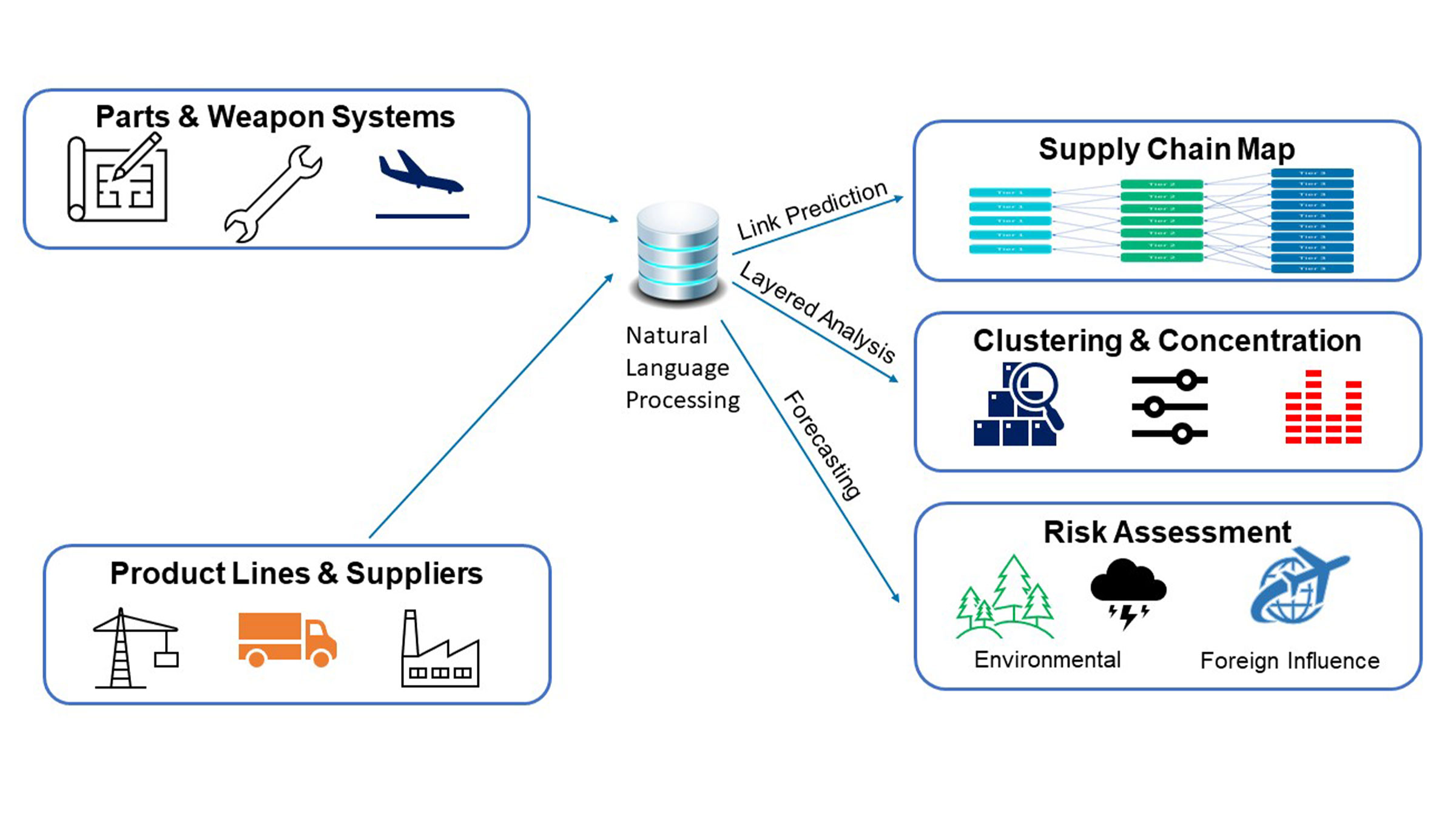

This collection effort would provide the nuanced information required to map and analyze supply chains with a high level of confidence and fidelity. Additionally, there are untapped databases that provide an easily searchable, subscription-based database of aircraft parts and subsystems of aircraft that includes a breakdown of system-level supplier information for over 1,200 aircraft programs.7 Overlaying data from these types of databases, the Air Force can begin to map the supply chain for its most vital weapons systems.

Transforming Data into Information

The second element of an Intelligence Community approach to managing the defense industrial base supply chain is to analyze both structured and unstructured data using manual and artificial intelligence/machine learning applications. The financial sector databases mentioned above are examples of structured data. Structured data is highly specific and is stored in a predefined format; this makes it readable and searchable by both humans and machines. Examples of structured data are found in a database or a spreadsheet, with each row an individual entry and each column a field or attribute of that entry. For example, a spreadsheet on baseball players may feature athletes (rows) based on their statistics (columns). With the right sources, one can compare multiple baseball players based on the number of home runs they have hit, what their batting average is, and how many runs batted in or stolen bases they have.

Analyzing structured data from multiple sources is like aggregating the important statistics for the players of interest in an upcoming game. No one source has all of the data, but when combined, a much fuller picture to base the analysis on emerges. One source might have a player’s overall batting statistics, but another source might have the player’s batting statistics against the pitcher they will face in tomorrow’s game. Each dataset is accurate and useful on its own, but putting them together gives the best likelihood of predicting an outcome. Likewise, piecing together publicly accessible commercial defense industrial base supplier data in a structured format allows an accurate and detailed supply chain map which could be developed for specific airframes of interest.

In addition to structured data, the analysis of unstructured data offers even more insight into DIB supply chains. Whereas structured data can be stored within a database or spreadsheet, unstructured data is a compilation of different types of data stored in its original format. This article is an example of unstructured data. Using natural language processing, machine learning algorithms can identify themes, meanings, and keywords, and in some cases even indicate which words are used to portray certain meanings.

Leveraging the Information

Initial research has shown that using machine learning to analyze EDGAR documents for supply chain mapping and risk assessment has been promising.8 In fact, there are already hedge funds and venture capital firms using this data to derive signals regarding tradability based on the information provided in these reports. This ingenuity has opened the door for more creative ways to analyze data for making operations decisions, and these firms’ trust in the accuracy and utility of this data should be compelling evidence that the military can benefit from this as well.

Natural language processing of EDGAR documents offers valuable information that can be used to analyze multiple aspects of a company’s risks and vulnerabilities as well as supplier relationships. Research has found additional analytic methods such as link prediction or clustering algorithms are beneficial in mapping supply chains and assessing supply chain risks.9 Once the supply chains are mapped, applying data analytics tools will allow the Air Force to overlay multiple supply chains to identify critical nodes that have an increased chance of disrupting the enterprise.

The third and final element of an intelligence approach to managing the defense industrial base supply chain involves forecasting supply chain disruptions and risks. Once the supply chain is mapped, the Air Force can anticipate risks similar to how forecasters predict the weather. Research shows forecasting and prediction markets can be used to accurately forecast nearly every future event impacting a supply chain.10 For example, the Air Force could identify a key supplier common to three out of the five large defense contractors and issue questions to web-based forecasters to determine the likelihood of this supplier going bankrupt in the next six months.11 If the forecasters identify a high likelihood, proactive contingency plans could be put in place in case this event occurs. The Intelligence Community started using forecasting to identify potential future outcomes with relative success after forecasters outperformed intelligence analysts in a competition from 2011 to 2014.12

Figure 2. Supply risk management example

The Time is Now

A resilient supply chain is critical to national defense. It is time for the Air Force to attack this complex problem with a military intelligence approach. Using multiple sources of information and analytical methods will help the Air Force gain a more accurate picture of its supply chain and allow it to better predict supply chain impacts and more effectively manage risks associated with supply chains. Technology that enables the service to better evaluate myriad supply chain data and more effectively address system complexities exists.

Implementing the solution outlined above will provide the Air Force with an innovative enterprise-wide view of its defense industrial base supply chain. China and Russia are pushing hard to reintroduce a multipolar world by increasing their military capability. Hopefully, efforts to increase resiliency in the Air Force’s defense industrial base supply chains are not too late.

__________________

Major Mark Boatman, USSF, serves as the deputy branch chief for Cyberspace Operations, Headquarters Space Operations Command, and holds a master of science in information security from the American Military University.

Lieutenant Colonel Jennifer Mapp, USAF, serves as the F-35 Lightning weapons materiel leader. She holds a master of business administration from William Carey University, a master of science in defense contract management from the Naval Postgraduate School, and a master of arts in defense and strategic studies from the College of Naval Command and Staff.

Lieutenant Colonel Nathan Olsen, USAF, is the special assistant to the executive director, Systems Engineering & Architecture, Office of the Under Secretary of Defense for Research and Engineering. He holds a master of science in engineering management from the Air Force Institute of Technology and a master of science in military operational art and science from the Air Command and Staff College.

Colonel Mark Szatkowski, USAF, serves as the director, Air/Navy/Air Defense Directorate, United States Embassy in Iraq, and holds a master of business administration in logistics and transportation management from the American Military University.

1 Yixin Wang et al., “When Ignorance Is Not Bliss: An Empirical Analysis of Subtier Supply Network Structure on Firm Risk,” Management Science 67, no. 4, https://doi.org/; Robert Handfield, Aruna Apte, and Daniel J. Finkenstadt, “Developing Supply Chain Immunity for Future Pandemic Disruptions,” Journal of Humanitarian Logistics and Supply Chain Management 12, no. 4 (2022); and Jan Henrich et al., “Future-proofing the Supply Chain,” McKinsey & Company (website), June 14, 2022, https://www.mckinsey.com/.

3 “The Biden-Harris Plan to Revitalize American Manufacturing and Secure Critical Supply Chains in 2022,” White House (website), February 24, 2022, https://www.whitehouse.gov/.

4 Michele Donaldson, “Team Illuminates Supply Risks That Impact Defense,” Air Force Materiel Command (website), August 31, 2022, https://www.afmc.af.mil/.

5 48 § C.F.R. 252.239-7018 Supply Chain Risk (December 2022).

8 Wang et al., “Ignorance.”

9 Luca Mungo et al., “Reconstruction Production Networks Using Machine Learning,” Journal of Economics Dynamics and Control 148 (March 2023), https://doi.org/.

10 Friedrich Hedtrich, Jens-Peter Loy, and Rolf A. E. Mueller, “Prediction Markets—A New Tool for Managing Supply Chains,” in Supply Chain Management, ed. Sanda Renko (London: IntechOpen, 2011).

11 “INFER is a Collective Intelligence Program Advancing the Forecasting Capability of the U.S. Government,” INFER (website), accessed October 17, 2023, https://www.infer-pub.com/.

12 Liz Brody, “Meet the Elite Team of Superforecasters Who Have Turned Future-Gazing Into a Science,” Entrepreneur, January 1, 2022, https://www.entrepreneur.com/.

The views and opinions expressed or implied herein are those of the authors and should not be construed as carrying the official sanction of the Department of Defense, the Department of the Air Force, Air Education and Training Command, Air University, or other agencies or departments of the US government.